Category:

Commercial

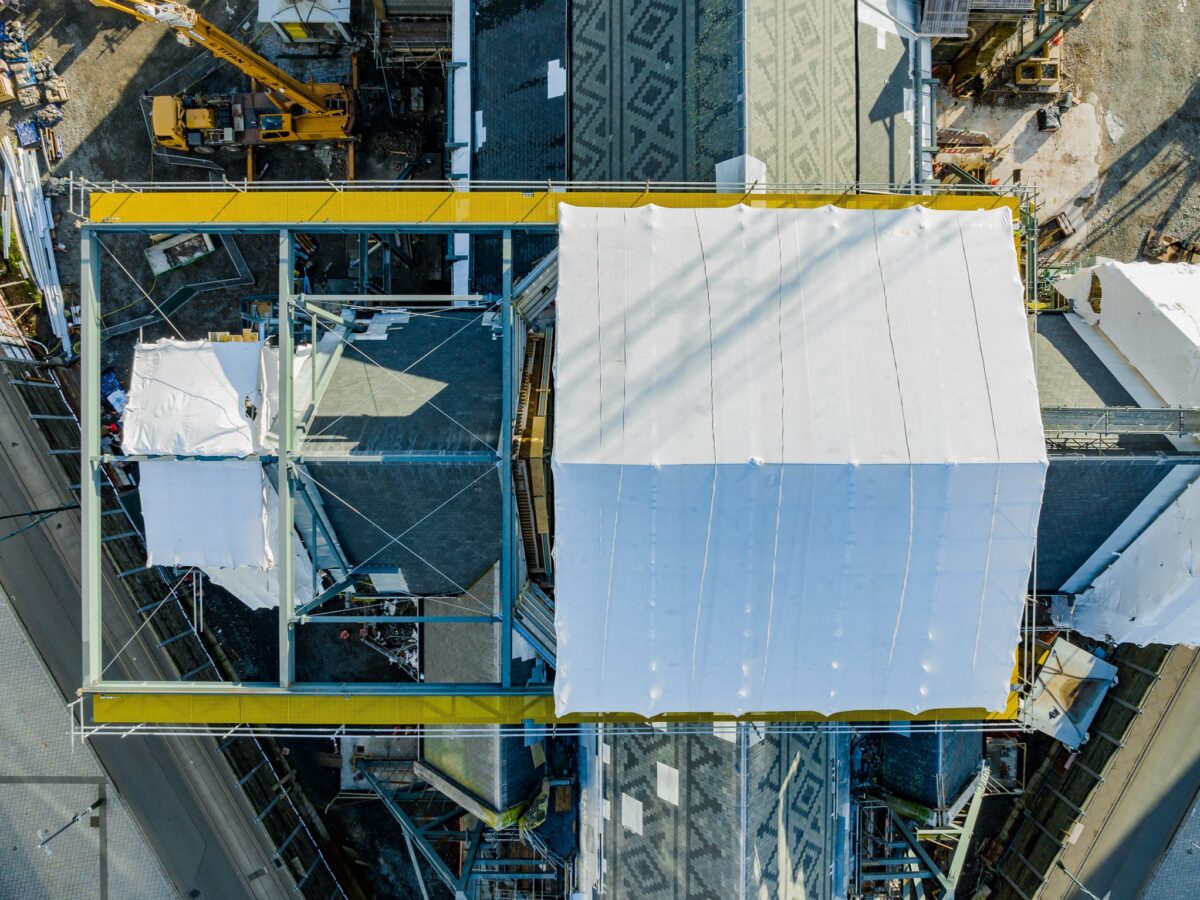

Christ Church

Cathedral 2022

Christ Church Cathedral

Location:

Christchurch CBD

Size:

100t & 281.1t

Works complete:

100t

The Stabilisation Phase is the first step to reinstating the Christ Church Cathedral, a Category 1 listed heritage building and iconic Christchurch landmark. The Stabilisation Phase addresses the structural damage, prevents further damage, and is crucial to gaining safe access to the building to carry out the subsequent strengthening and reinstatement construction phases.

This project has necessitated an extreme focus on health and safety, heritage, cost and time management, and has required collaboration between VIP Steel, Naylor Love and Holmes Consulting to ensure best methodology and constructability. VIP Steel have used the latest 3D scanning technology, surveying the building from a 15m distance due to risk and plotting the building surfaces for stabilisation frame design, ensuring flawless installation.

The South Transept frame contains single columns spanning 15m which are 5T per column. The frame was assembled on-site due to its final size and weight, 20m high and 24T. The West Wall Frame is 17T and has been installed using a 250T crane. Although it is not the heaviest, it is a significant piece of steel as it is permanent structure which includes a steel plate affixed to the frame with the date installed, for the purposes of recording it in the heritage documentation. Eventually, this frame will be enclosed and house the large Rose Window.

Subsequent stabilisation phases will include the North Transept, and the Apse which wraps around the back of the building.

281.1t

Packages 4-6 complete the stabilisation phase of the Cathedral. This project has demonstrated the advantage of steel – no other common building material could effectively stabilise a building of this scale while limiting further damage to the heritage fabric. Chrome-plated bearing pins made of condition “T” high-tensile steel on the Package 4 and 5 link beams were innovatively designed to efficiently meet the structural requirements and save material in the design.

Effort was made on a design level to incorporate the Package 4 steltech temporary beams into the final design – leading to a significant reuse of material and improved project sustainability.