Category:

Large Commercial

Performing Arts

Performing Arts

Location:

Christchurch CBD

Size:

200t

Project overview:

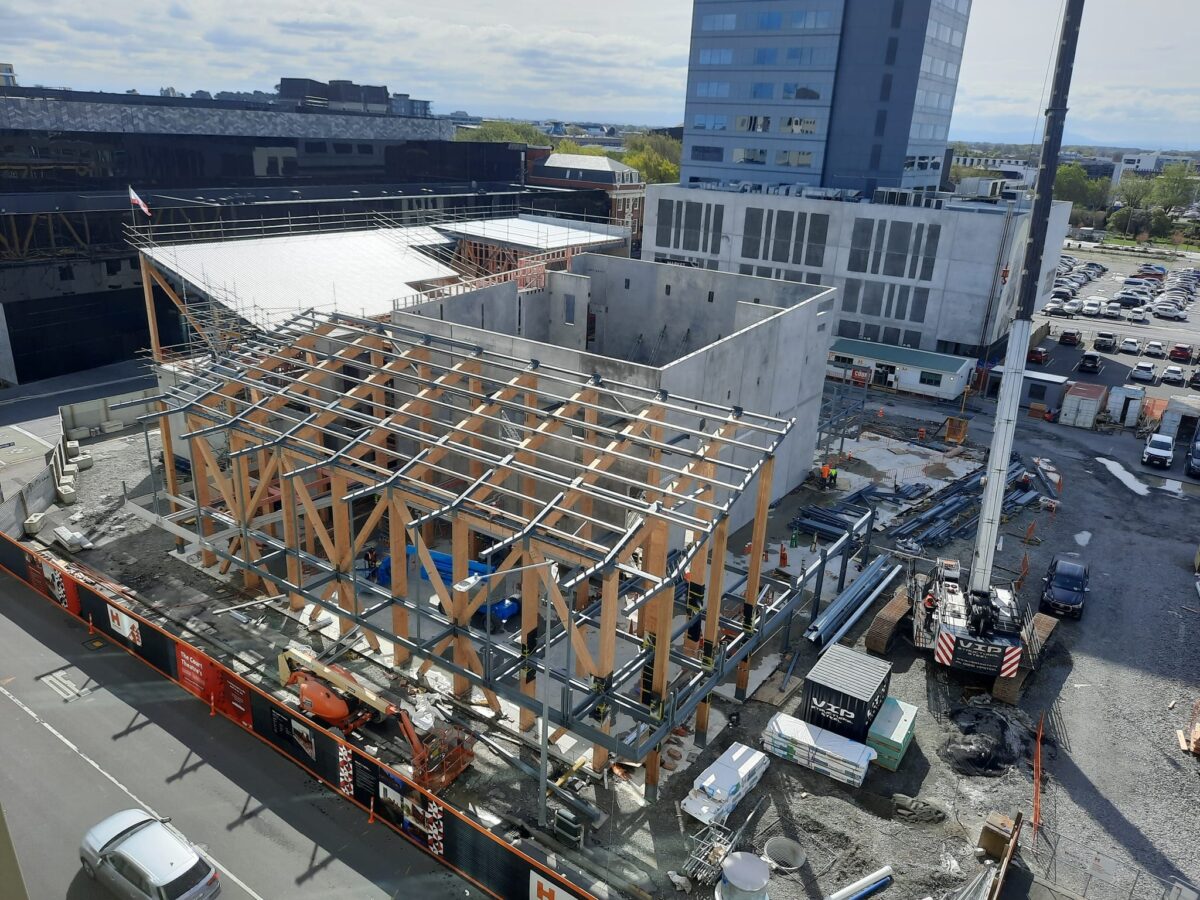

The Performing Arts Precinct (Te Whare Tapere) provides first-rate facilities for music, drama, dance and other performing arts. The Court Theatre is located within the proposed Performing Arts Precinct and provides a new home for the theatre company, which was displaced by the Canterbury earthquakes. The three-storey building hosts three theatre spaces as well as supporting front-of-house and back-of-house functions.

There were five construction zones and the building features seven different roof angles, angled walls, balconies and canopies. This complexity drove the biggest challenge: multi-phasing and integration of the steel build with other trades. The team had to contend with a tight workspace – 3,150 individual steel items were installed within a 1,700sqm footprint, road-locked on two sides, making the interface between all trades challenging.

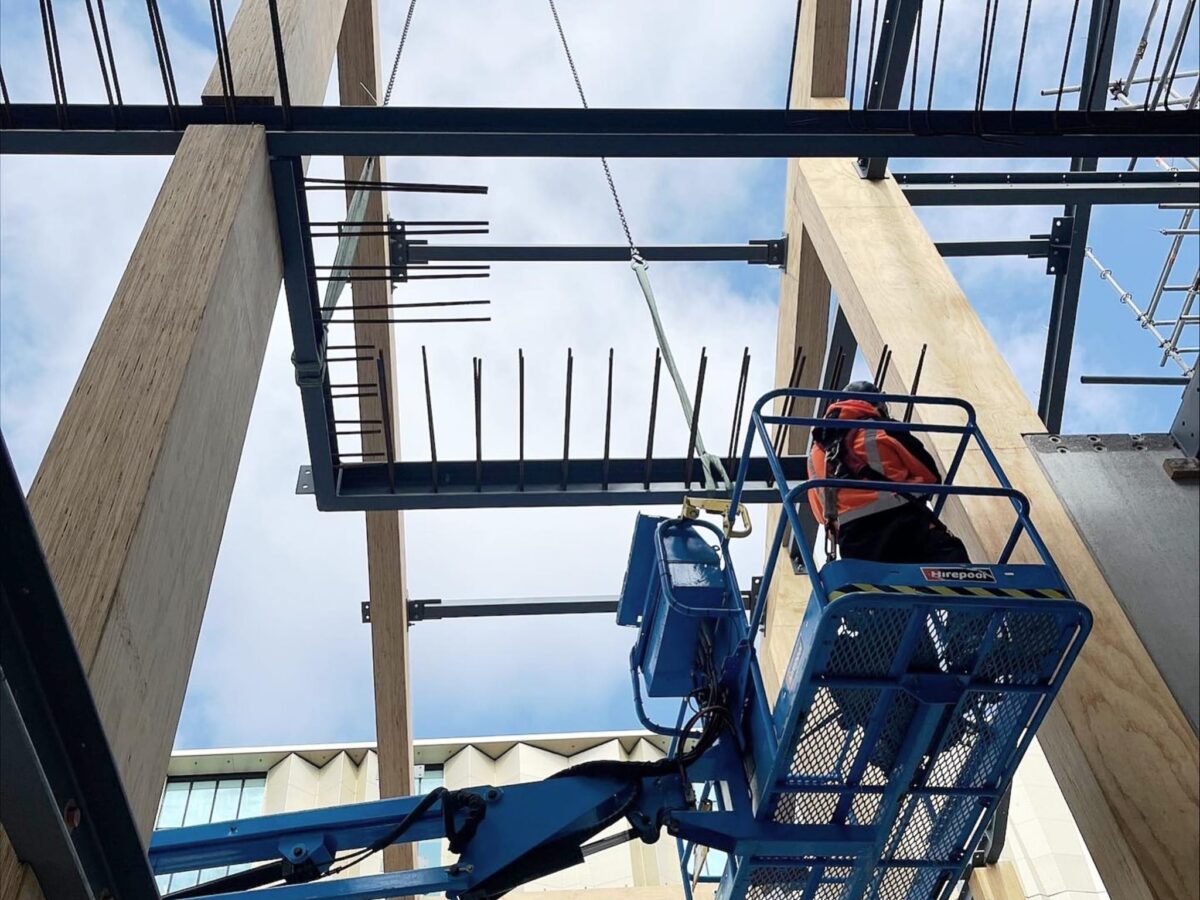

Theatres are inherently complex buildings with dynamic structural systems that exist not only to support the dead loads of the building, but also the high variable live loads within the spaces. Primary steelwork trades needed to be configured and sequenced around other primary structural systems such as mass timber and precast elements. Secondary steelwork members had to meet tight design and installation tolerances for highly bespoke theatre equipment.

The main auditorium features a complicated roof structure and presented many design constraints, such as needing to support four catwalks, a complex array of pulley and gantry systems, stage lighting and sound, and heavy acoustic ceiling. There were more than 4,200 separate components on the critical path; precision during steel fabrication was crucial.

The steel constructor had multiple meetings to ensure everything was regularly reviewed and avoid clashes. An additional complication factor was the architectural and theatre design elements that led to the roof requiring three levels of seismic bracing.

An engineered timber solution was initially considered; however, it quickly became apparent that it was costly, complex and posed unnecessary risk to the project. Given all the constraints, steel was the only option thanks to its high strength and stiffness relative to weight, and its ability to be fabricated to suit complex geometry.

Numerous structural systems and materials feature throughout the building, including precast concrete panels and engineered timber elements; steel was instrumental in connecting the separate elements.